Image commercially licensed from Unsplash

It’s every product creator and designer’s dream to come up with something significantly different, complex, and beautiful that people love. But what they don’t know is how to get the necessary components for such an innovative idea. With high-level technology parts becoming difficult to source, designers face this problem on a regular basis. In this blog post, we will discuss various methods of finding doable solutions in order to manufacture your unique product designs without breaking the bank. Whether your requirement is development boards or generic chipsets, stay tuned for tips on getting the required elements at reasonable prices!

Research your product and identify the components you need

When it comes to developing a product, research is key. By dedicating time to recognize the necessary components, you can guarantee the development of a solution that genuinely satisfies your customers’ requirements. Every element, spanning from hardware to software, holds significant significance in the triumph of your product. By doing your due diligence and researching each option available to you, you’ll be able to make informed decisions and create something that truly stands out in the market. So don’t rush the process. Take the time to research your product and identify the components you need to make it the best it can possibly be.

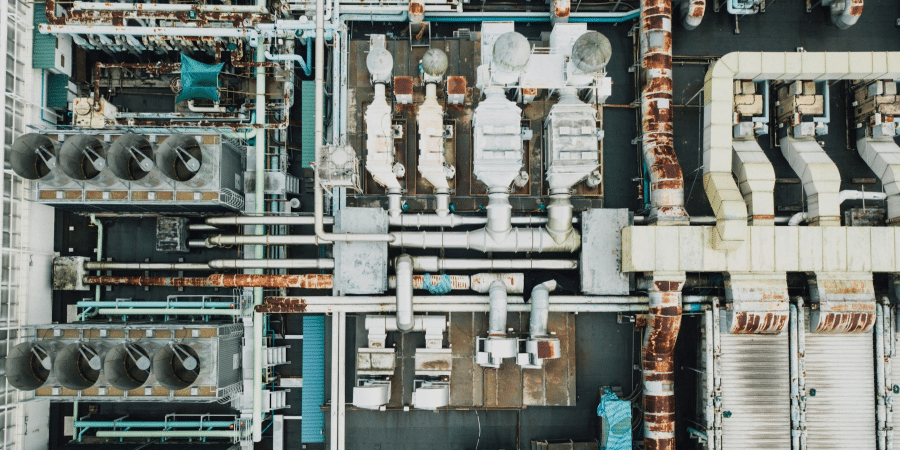

Decide between thermoforming and plastic injection molding

When it comes to manufacturing plastic parts, two popular options to consider are thermoforming and plastic injection molding. If you live in the US, thermoforming or plastic injection molding is one of the decisions you’ll keep going back to as a business owner. While both methods offer their own unique advantages, deciding which one to use ultimately depends on a variety of factors including the desired geometry, production volume, and material requirements. Thermoforming, for instance, is ideal for creating large and complex shapes with lower production volumes, whereas plastic injection molding is better suited for the high-volume production of smaller, intricate parts. Ultimately, the key to making the right decision is to carefully evaluate the pros and cons of each method and consider the specific needs of your project.

Consider secondary sources

When searching for replacement parts for your car or machinery, it’s important to consider all options available to you. While brand-new parts from official dealerships may seem like the most reliable choice, they can often come with a hefty price tag. This is where secondary sources come in handy. Online retailers and used parts suppliers offer a wide variety of alternatives to brand-new parts, often at a much more affordable price without compromising on quality. Not only can these sources save you money, but they can also broaden your search for parts that may be harder to find through traditional channels. Don’t limit your options – explore all avenues when seeking out replacement parts.

Compare prices

Finding the best deal on parts for your project can seem like a daunting task. With so many options available, it can be overwhelming to try and compare prices, shipping costs, delivery times, and quality of parts from different sources. However, taking the time to research and compare your project to others’ can ultimately save you both time and money. By exploring a variety of sources, you can ensure that you are getting the best possible deal without sacrificing the quality of the parts you need. So, whether you are working on a personal project or a professional endeavor, taking the time to do your homework can pay off in the long run.

Contact your suppliers

When it comes to running a successful business, communication is key. This rings especially true when it comes to working with suppliers. If you have any questions or special requests regarding the components or services they provide, don’t hesitate to reach out and start a dialogue with them. Building a strong relationship with your suppliers not only ensures that you receive the best possible product or service but also creates a sense of trust and reliability between both parties. So, make that call or send that email and start building that bridge to success!

When making a product or choosing parts for your project, it pays to do your homework. Research what components you need and compare the various options available to find the best fit for you. Don’t forget to factor in secondary sources like online retailers and used parts suppliers for potentially more cost-effective solutions. And when all is said and done, make sure to reach out to your potential suppliers with any questions or special requests. Doing these things can help ensure that you get the parts you need at the lowest price possible without sacrificing quality or deadlines. Now go forth on your journey of research; start small and expand as needed!