In the construction and mining industries, aggregate screens play a crucial role in the processing and classification of various materials. Selecting the appropriate type of aggregate screen can significantly impact the efficiency and quality of the final product. This comprehensive guide explores the different types of aggregate screens, their specific applications, and the advantages they offer.

What is an Aggregate Screen?

An aggregate screen is a mechanical device that separates and classifies different sizes of aggregate materials, such as sand, gravel, and crushed stone. These screens are essential in ensuring the quality and consistency of materials used in construction projects, including roads, buildings, and infrastructure.

Types of Aggregate Screens

Vibrating Screens

Vibrating screens are one of the most common types of aggregate screens. They utilize vibration to move materials across the screen surface, allowing smaller particles to pass through the openings while larger particles remain on top. These screens are highly efficient and can handle a wide range of materials.

Applications: Ideal for sorting and grading materials in mining, quarrying, and recycling operations.

Advantages: High efficiency, handling large volumes, and customizable screen sizes.

Trommel Screens

Trommel screens are cylindrical drums with perforated sides that rotate to separate materials based on size. As the drum rotates, smaller particles fall through the holes while larger particles continue to move along the drum’s length.

Applications: Commonly used in waste processing, composting, and aggregate screening.

Advantages: Effective for screening moist and sticky materials, easy to maintain, and versatile.

Grizzly Screens

Grizzly screens consist of a series of heavy-duty bars or rails set at a specific angle. These screens are used to initially screen large rocks and boulders, allowing smaller materials to pass through while retaining the larger ones.

Applications: Suitable for primary screening in mining and quarrying operations.

Advantages: Robust construction, handling large and heavy materials and low maintenance.

Plain Weave Screens

A plain weave screen is a woven wire screen that provides precise and consistent openings. These screens are commonly used for fine screening and classification of materials.

Applications: Used in construction, mining, and industrial processes for fine material screening.

Advantages: High precision, durability, and cost-effectiveness.

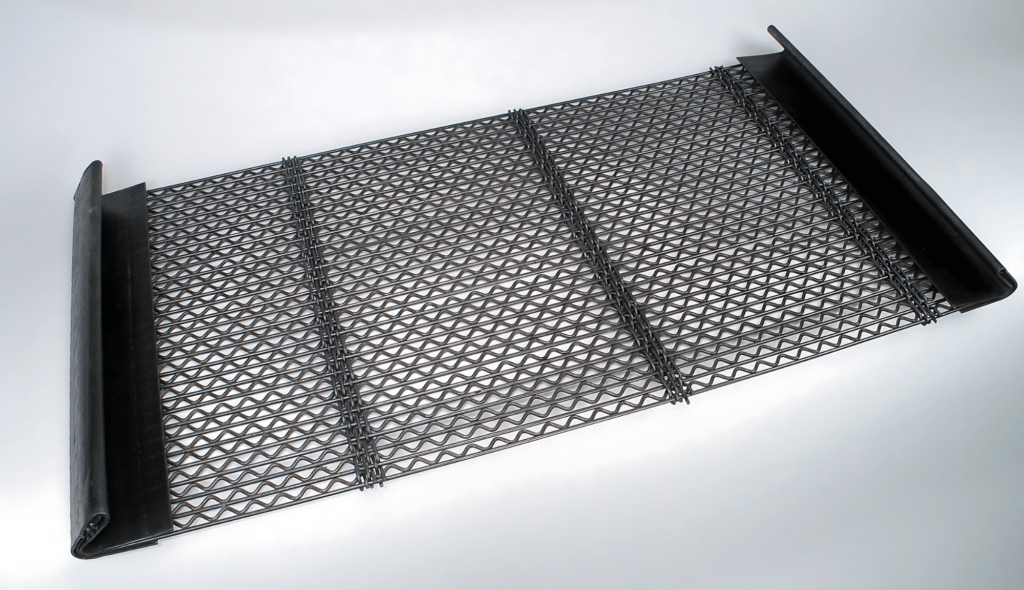

Self-Cleaning Screens

Self cleaning screens are designed to prevent clogging and blinding and ensure continuous operation. They feature unique wire configurations that allow the screen to flex and release trapped materials.

Applications: Ideal for screening materials prone to clogging, such as damp or sticky aggregates.

Advantages: Reduced downtime, increased efficiency, and minimal maintenance.

Piano Wire Screens

Piano wire screens are made from individual wires that are tensioned and arranged parallel to each other. These screens offer high open areas and excellent screening efficiency, making them suitable for fine and difficult-to-screen materials.

Applications: Used in quarrying, mining, and recycling for fine and accurate screening.

Advantages: High open area, efficient material separation, and adaptability to various materials.

Optimizing Aggregate Screening

To optimize aggregate screening, choosing the right screen type for the specific application is essential. Factors to consider include the material type, moisture content, particle size, and desired throughput. Additionally, regular maintenance and inspection of screens are crucial to ensure optimal performance and longevity.

Final Thoughts

Understanding the different types of aggregate screens and their specific applications is crucial for optimizing material processing in the construction and mining industries. By selecting the right screen and maintaining it properly, you can ensure efficient and high-quality screening results.

For more information on the various types of aggregate screens and to find the right screening solutions for your project, visit SRK Metals. Explore its range of products, including plain weave screens, self-cleaning screens, and piano wire screens, and discover how it can help you achieve superior screening performance.

Published By: Aize Perez